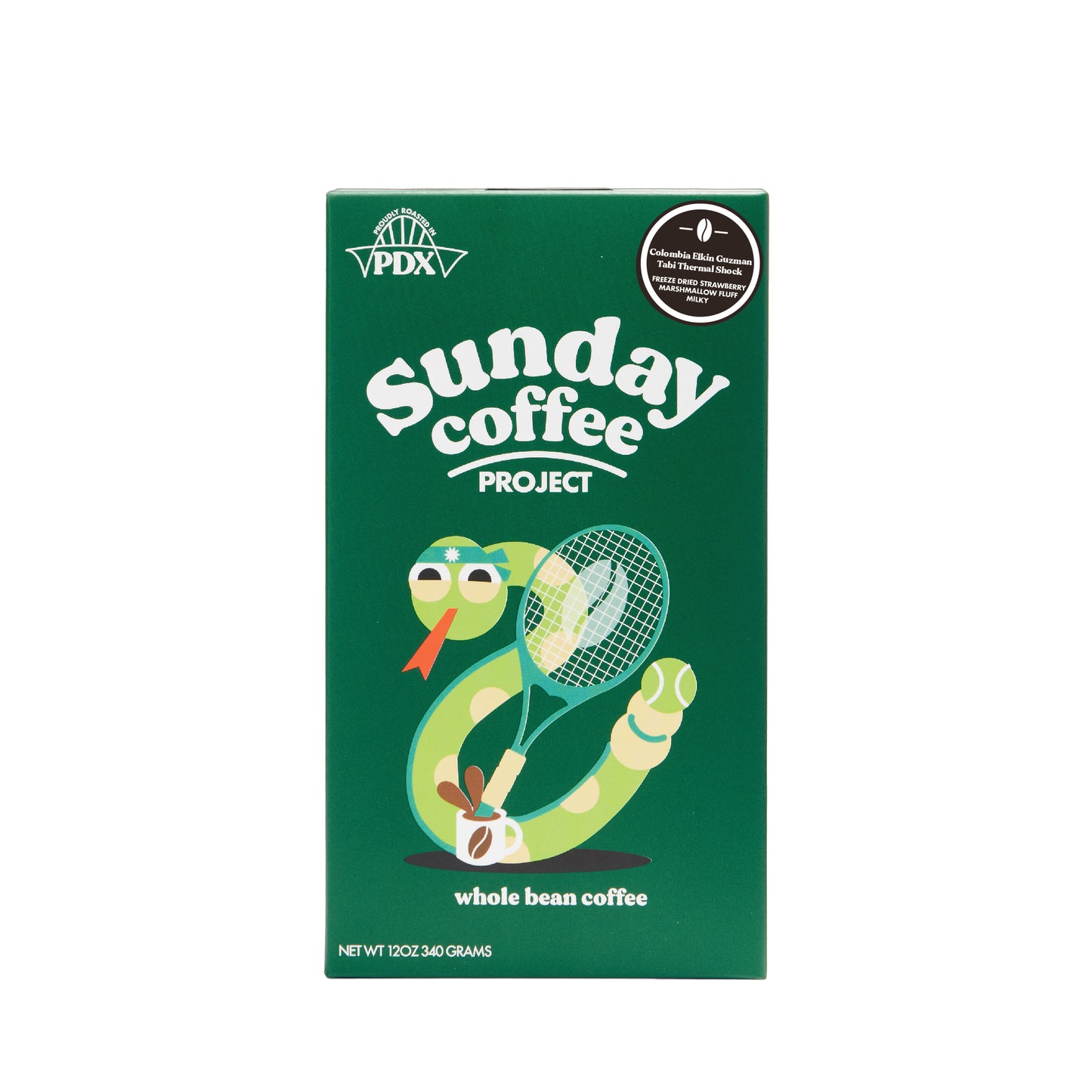

Colombia Elkin Guzman Tabi Thermal Shock Natural

Colombia Elkin Guzman Tabi Thermal Shock Natural

Couldn't load pickup availability

Tasting Notes: Freeze dried strawberries, marshmallow fluff

Processing: Thermal Shock

Producer: Elkin Guzman

Location: Huila, Colombia

Altitude: 1650masl

Varietals: Tabi

Bio:

Located in the village of El Portal in Huila, Colombia, El Mirador is a 31-hectare farm growing varieties such as Caturra, Tabi, Catiope, Orange Bourbon, Striped Bourbon, and Mokka. The owner, Elkin Guzman, has been immersed in coffee cultivation, trading, and retail since birth, with his family celebrating over 70 years in the coffee industry and dedicating 12 years to researching post-harvest processing techniques. Elkin utilizes multiple processing methods for each coffee lot, including Coffee Maceration, Lactic and Acetic Natural processes, and Natural Hydro Honey, based on extensive research and experience.

Harvest and post-harvest procedures are highly standardized to ensure consistency and quality. Initially, the sugar content of the coffee cherries is measured in degrees Brix, followed by density and volumetric separation. Based on these measurements, the most suitable processing method is chosen to maximize each lot’s potential. Elkin’s innovative spirit is reflected in his diverse fermentation and drying techniques, tailored to enhance each coffee’s unique characteristics.

The Tabi variety, developed by CENICAFE, is a cross between Tipyca, Bourbon, and Hibrido de Timor, designed to provide a rust-resistant alternative for certain regions. Tabi plants are characterized by tall, elongated branches with secondary and tertiary formations, and mostly red fruits, though some may be yellow, with light green leaves.

For this lot of Tabi coffee, El Mirador’s team selected Thermal Shock processing. This method involves controlling the temperature during fermentation. The coffee is placed in plastic tanks to create an anaerobic environment for 60 hours, then moved to larger tanks for oxidation. Water at 35˚C-40˚C is added to maintain a constant temperature throughout the coffee mass for another 60 hours. Subsequently, the water is removed, and cold is applied to halt fermentation for 8 hours. The coffee is then dried for 18 to 24 days, resulting in greater sweetness, balance, and acidity, and fixing unique sensory attributes by managing temperatures at each stage.

After the thermal shock process, the coffee is dried in a dark room to optimize the environment, ensuring continuous drying day and night. Humidity and temperature are controlled with dehumidifiers, extractors, and fans to create a dry, airtight environment, reducing humidity by 1.5% during the day and 0.6% to 1% at night. This method provides a consistent drying time of 12 to 15 days and enhances the sensory profile of the coffee, producing a cleaner beverage with unique notes compared to traditional natural drying methods.

In this drying process, the coffee is arranged on beds and in baskets to maximize drying volume per area. The aim is to minimize fermentation time to express the terroir and genetics of the variety. Short fermentation periods of 36 to 48 hours are used, with cherries disinfected in water with citric acid at temperatures between 25˚C and 35˚C.